Owing to its exceptional properties, concrete is one of the most extensively used materials for construction. The creation of building elements using concrete involves pouring it into specially designed molds commonly known as shuttering or formwork. Formworks can be created by using permanent or temporary molds for holding the concrete in shape until it becomes strong enough to support itself by hardening.

Formwork plays a fundamental role in all types of concrete constructions. It must offer the necessary load-bearing capacity for casting operations and be able to hold its shape during the hardening of the concrete.

Requirements of Good Formwork:

Mentioned below are some of the general performance features that must be met by formworks used for concrete construction.

- Withstanding live and dead loads

- Retention of shape with adequate braces and props

- Reusable material, as lightweight as possible

- Leakproof joints

- Removal process must not cause damage to the concrete surface

- The formwork material should not distort or warp.

The pressure exerted by concrete depends on its type and pouring temperature. Therefore, both these factors must be taken into account while selecting formwork. Also, it is important for the formwork to resist the load exerted by dry as well as wet concrete. In order to avoid any movement during construction, formwork requires poles and stabilizers that are also referred to as falsework.

According to Doka, some of the most commonly used formworks are as mentioned below.

Timber Formwork: This is one of the earliest types of formworks used in concrete construction. These formworks are extremely flexible and can be assembled on site. It offers a number of advantages such as

- Ease of production and removal

- Lightweight compared to metallic formwork

- Can be created in any size, shape, and height

- Can be an economic alternative for smaller projects

Plywood Formwork: Often used in conjunction with timber, this manufactured wooden material is available in different thicknesses and sizes. It is primarily used for form linings, decking, and sheathing in formwork applications. In terms of weight, strength, and durability, the properties of plywood formwork are similar to that of timber formwork.

Plastic Formwork: Made of lightweight and robust plastic, these formworks are assembled from modular systems or interlocking panels. Plastic formworks are best suited for small projects such as low-cost housing estates with repetitive tasks.

Plastic formworks are suitable for multiple reuses and large sections and can be cleaned with water. However, as many of its components are prefabricated, it offers considerably lower flexibility compared to timber.

Metallic (Steel and Aluminum) Formwork: As a result of its multiple reuse capability and long service life, steel formwork is considered to be extremely useful. Though expensive, it is considered to be extremely viable where the user has multiple reuse opportunities. Some highly appreciated features of steel formwork include

- Strength, durability, and long lifespan

- Provides smooth surface finish on concrete

- Reduces concrete’s honeycombing effect

- Can be installed and dismantled easily

- Can be used for curved structures

Though aluminum formworks are almost similar to its steel counterpart, it has a relatively lower density. This makes aluminum formworks lighter than and not as strong as steel formworks.

Permanent Insulated Formwork: Used for permanent insulation, these formworks are considered to be one of the most advanced formwork systems. These formworks often provide additional acoustic, thermal, and fire-resistance properties. They also reduce the building sector’s environmental impact by offering energy efficiency and sustainability.

Stay-In-Place Formwork: The formworks are designed to function as shear and axial reinforcement by remaining fixed after the concrete has set. They also provide resistance to corrosion and environmental damage and are used extensively in piers and columns.

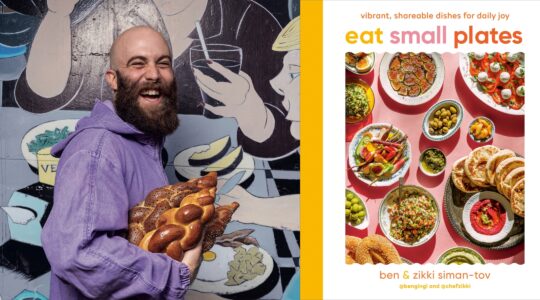

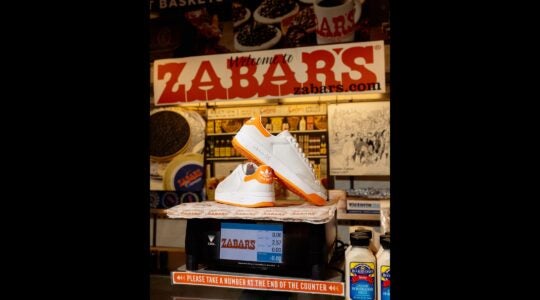

The New York Jewish Week brings you the stories behind the headlines, keeping you connected to Jewish life in New York. Help sustain the reporting you trust by donating today.